MANUALLY CONTROLLE D BUTTERFLY VALVE

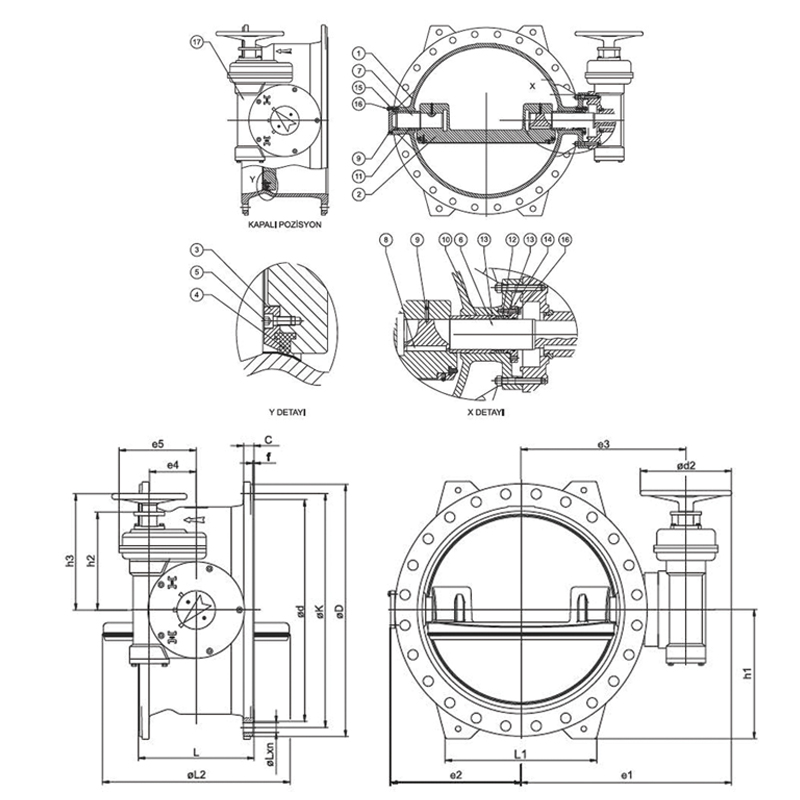

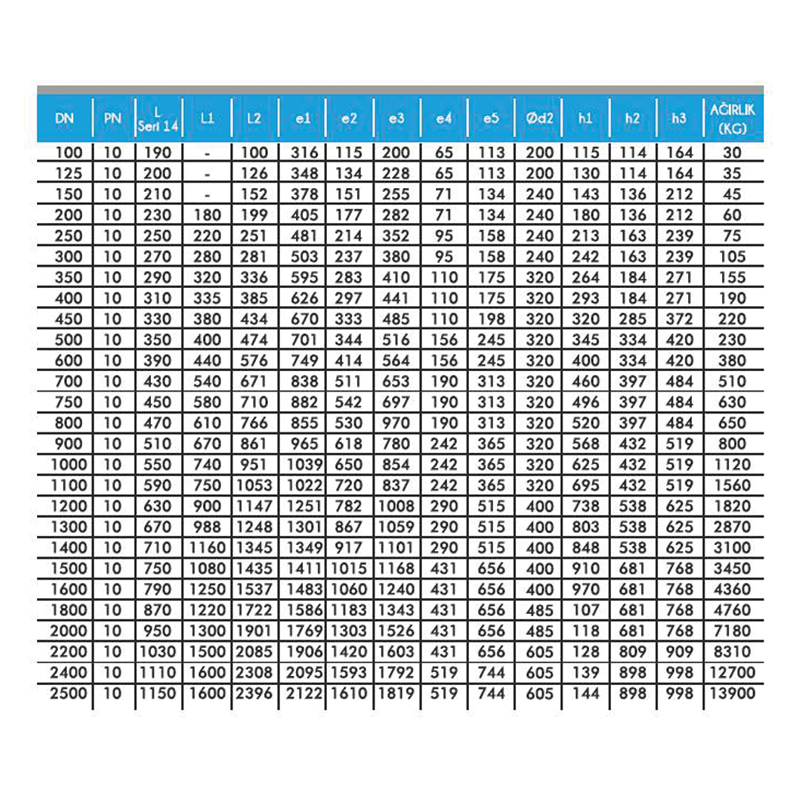

Valve was designed such that it will present minimum resistance for valve housing and flaps. Sealing is maintained by T section sealing ring which is fixed with fixed by peripheral press ring next to flap. Sealing is maintained certainly at both direction since sealing ring presses over housing seat which was processed conically when flap is closed positions. Sealing ring can be replaced easily without requiring to dismantle the flap. Seat surface is resistant against abrasion and corrosion since it was manufactured from hard chromium or AISI 316 Stainless steel welding filler. Our butterfly valves are manufactured as double eccentric. Aim of first eccentric is to lower pressure which is present over rubber sealing ring when valve is opened, removal of corrosive effect and maintaining continuous contact between sealing ring and housing seat. During opening process, rubber sealing easily disconnects from housing seat surface by means for second eccentric. There is design for Double parted shaft which increases passage section. Valves are maintained to have longevity without requiring maintenance for the valves by O-ring system which is built over self lubricating sleeves which are made of brass and delrin. Gearbox maintains quarter tour (90 degrees) movement which is required by butterfly valves. Gearboxes are designed such that they will ensure butterfly valves to be opened by one person under rated pressure by rotating flywheel manually. It is lockable type and it does not allow forces which influence flap due to flow conditions to rotate flap. Outlets of gearboxes are manufactured to be suitable for installation of any kind of electrical actuators. DESIGN: They are manufactured accordingly with TS EN 592 Connection Length: TS EN 558*1 Flange Connections: EN 1092-2; ISO 7005-2

© 2018 Pınar Vana. All rights reserved.